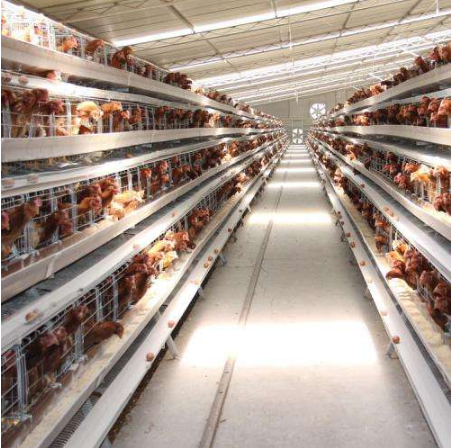

When laying hens are used in laying hen cages, they generally start to enter the cage from 8 weeks of age, and are eliminated from the cage when they are raised to 72 weeks of age to complete a production cycle. Therefore, under the coordination of good chicken house environmental conditions, there must be a reasonable structure of the poultry battery cage, so that the laying hens can exert their highest production efficiency.

The size of the laying hen cage in Australia must be able to meet its certain activity area, feeding position and height. At the same time, in order to allow the eggs laid out to roll out of the cage in time, the bottom of the cage should have a certain inclination. According to the above requirements, the arrangement of laying hen cages must consist of many small single cages. There are several ways to raise 3 or 4 chickens per cage, and 6 or 8 chickens.

The size of the single cage of the laying hen cage is generally 380-450 mm high in the front and 300 mm high in the rear. The bottom slope of the cage is 9-10 degrees, the depth of the cage is 350-600 mm, and the egg-collecting trough extending out of the cage is 120-160 mm. The cage width depends on the feeding position, and the feeding position of each chicken is 100-110 mm.

There are two types of manufacturing and installation of single cages, namely integral and assembled. The integral type is composed of a single unit cage of several units. Its characteristic is that it is easy to install, but it consumes materials, and it is difficult to handle and deform easily after it is made. The assembly type adopts the integral cage frame, and the manufacturing and installation of the single cage has two forms, namely the integral type and the assembly type. The integral type is composed of a single unit cage of several units. Its characteristic is that it is easy to install, but it consumes materials, and it is difficult to handle and deform easily after it is made. The assembled type adopts the integral cage frame. After the integral cage frame is installed, hang the fan cage nets and serve. It is characterized by neat installation, replacement and maintenance power. The assembly type is more common in actual production.

The fan cage nets of the single cage are generally made of cold drawn steel wire spot welding, but the function of each fan cage net is different, and their material thickness and mesh size have different requirements.

The side net and the back net are mainly used as the space between the cages, and can be distributed into horizontal grids by using metal wires with a diameter of 2 to 2.5 mm. The thick wires in the warp direction are arranged outside, with a spacing of 100 to 200 mm; the fine wires in the weft direction are arranged on the inside, with a spacing of 30 mm, which can prevent the chickens from pecking.

The bottom net must not only bear a certain weight, but also drop feces and eggs, and must have a certain elasticity, so that the eggs are not easy to break when laying, and the chicken has a certain sense of comfort when moving. Therefore, use a metal wire with a diameter of 2.5 to 3.0 mm to distribute it into a vertical grid. Thick wires in the warp direction are arranged on the surface with a spacing of 22-25 mm; fine wires in the weft direction are arranged underneath with a spacing of 50-60 mm, so that the eggs can roll out smoothly along the slope of the warp direction.

The width of the cage door of the laying hen cage depends on the width of the single cage. Generally, a 3 mm diameter wire is welded into a vertical fence with a spacing of 50-60 mm. The height of the cage door is 400 mm, and the lower edge of the cage door should be 50 to 55 mm from the bottom net to leave a gap. Or add an egg guard plate at a distance of 50 mm from the lower edge, and extend it into the cage obliquely to prevent the eggs in the egg collection tank from being pecked by chickens, as well as chicken manure leaking into the feed tank and water tank.